|

|

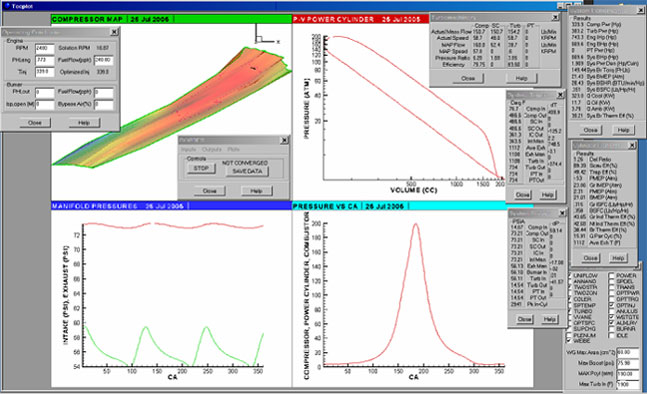

Engine Simulations

Virtual Dynamometer - Windows Interface

This package is the first, true virtual engine that can give designers and engineers a powerful software tool that integrates and comprehensively analyzes major engine systems in an interactive Windows environment. It combines a detailed resistor-capacitor network solver of thermal energy distributions throughout the engine system, with a thermodynamic performance and emissions analyzer to provide virtual engine simulations for a variety of reciprocating engines. This model has the capability of predicting both cycle-resolved and integrated performance parameters such as volumetric efficiency, gross and net imep, fmep, bmep, torque, power, gas composition (i.e.- air, unburned gaseous fuel, combustion products), gas temperature, pressure, velocity, mass flow, transient thermal energy distributions, fuel evaporation rates, heat release, etc. These tools are also capable of examining cylinder-to-cylinder variations. These capabilities, coupled with powerful pre- and post- processors allow for efficient design and optimization of intake and exhaust system layout and geometry, port design, cam profile development, valve sizing, combustion chambers and even turbocharged engine systems.

The Virtual Dynamometer is not only an excellent design and optimization tool, but is also a powerful teaching model, to view how design changes affect the thermodynamics of the engine system. The Windows interface allows design parameters to be modified, with new results instantly displayed in an easy to understand graphical layout.

Contact Laura Dillmann for a Thermodynamics Training Class Using TECAT Engineering's Virtual Dynamometer Tool

Copyright © 2008 TECAT Engineering, Incorporated. All Rights Reserved.