|

|

|

| |

|

|

|

| Engine

Simulations

Hybrid Electric

Vehicle Engines

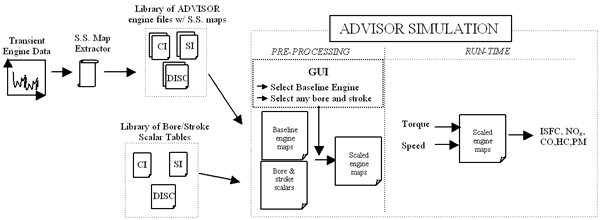

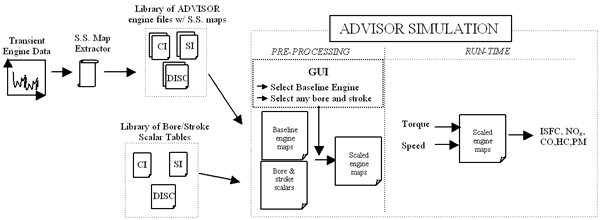

TECAT Engineering has

developed an algorithm to predict the performance and emissions for families

of engines used within a hybrid electric vehicle simulator. This algorithm

has been incorporated into the ADVISOR and PSAT Hybrid Electric Vehicle

models. ADVISOR is the ADvanced VehIcle SimulatOR developed at the National

Renewable Energy Laboratory. PSAT, the Powertrain System Analysis

Toolkit, was developed by Argonne

National Laboratory and is sponsored by the US Department of Energy.

Both tools have been developed to assist the automotive engineering community

to quickly simulate the performance of a large number of vehicle design

options. |

|

|

|

This

TECAT Engineering algorithm is based on a scalar model of existing engines. Taking user

defined bore and stroke, the algorithm predicts the brake specific quantities

of NOx, CO and fuel consumption. An oil film adsorption/desorption model

and a crevice flow model have been added to the algorithm to predict exhaust

hydrocarbons as well. The resulting emissions and performance maps at various

engine displacements are then used within one of the HEV simulators mentioned

above, to determine optimal sizing between the internal combustion engine

and the electric drive system, subject to known driving schedules and charging

strategies.

|

|

|

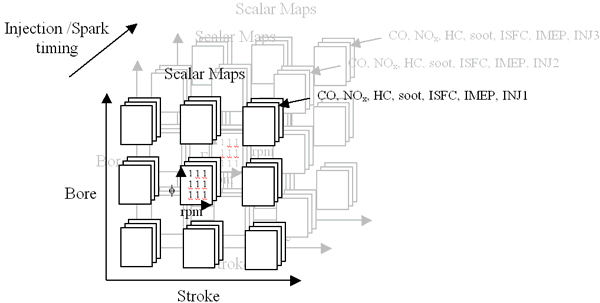

| The

scaling algorithm uses steady state data engine data and scaling factors

generated from simulated WinKiva results for various combustion chamber

shapes. The engine data and scaling factors are then combined to predict

performance and emissions data for any engine size. When steady state engine

data is not available, the algorithm can extract the data from transient

engine schedules. This technique has been numerically validated by comparing

actual steady state simulated maps with steady state maps created from transient

schedule simulations. At each bore and stroke, a torque vs. speed sweep

is performed to evaluate performance and emissions over the entire engine

map. The scaling algorithm can then interpolate within the resulting data

for any bore, stroke, torque and speed input. The algorithm may easily be

expanded to include the effects of operating conditions such as the injection/spark

timing. |

|

|

|

| |

|

Copyright

© 2008 TECAT Engineering, Incorporated. All Rights Reserved.

|

|

|

|

|

|

|